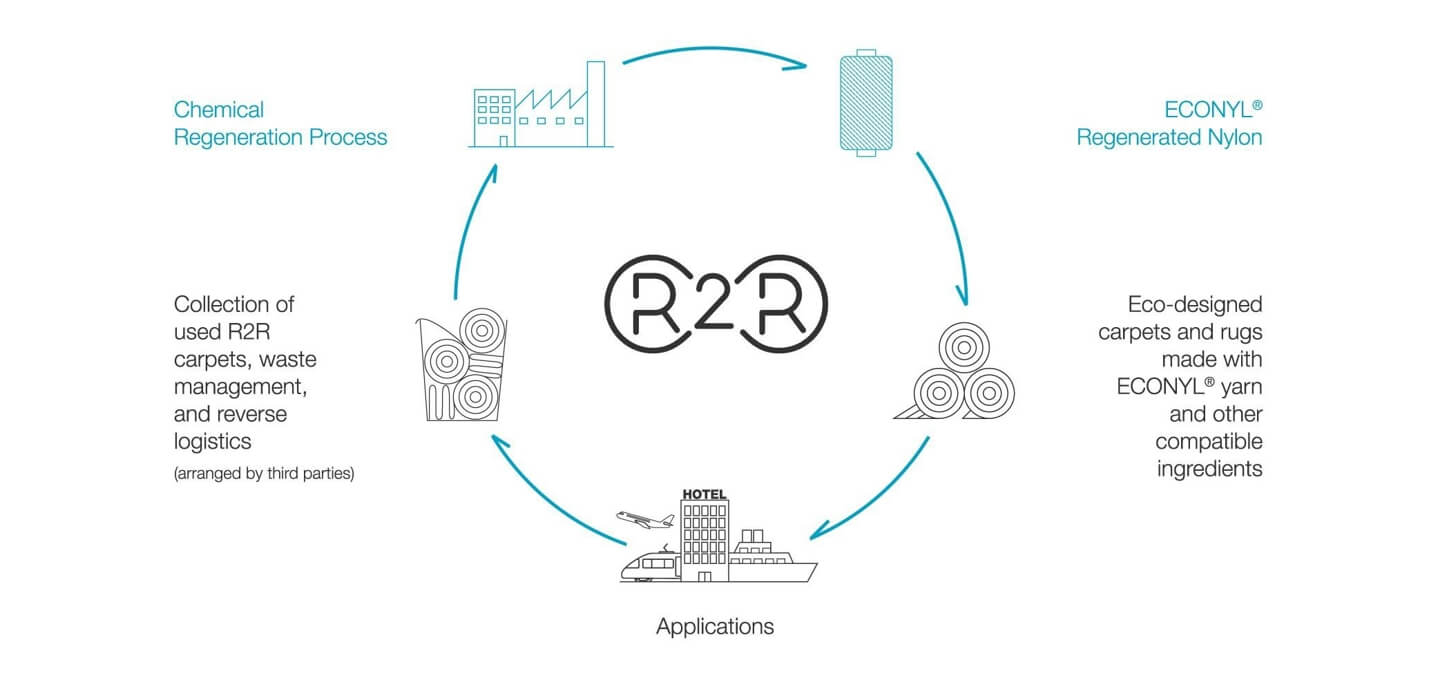

R2R production cycle

Sustainable all round

The ‘R2R –Born Regenerated to be Regenerable’ recycling process from our yarn manufacturer and partner Aquafil ensures that carpets can be fully returned to the production cycle at the end of their useful life. This means that old carpets are turned into new ones – without any loss of material and with a minimal ecological footprint.

An innovative and pioneering concept for converting waste into valuable resources.

1. Labelling for recycling

The carpets are furnished with the ‘R2R’ label during production. This ensures that the carpet is recognised as recyclable later - even if the original manufacturer is no longer known.

2. Separation of materials

A carpet consists of different materials, usually polyamide 6.0 yarn and backing material.

Before recycling, these two components are separated from each other using heat.

3. Regeneration of the raw materials

After separation, the materials are cleaned, processed and made usable again with a special technique.

4. Return to the production cycle

The regenerated materials are reused by the suppliers to produce new carpets - with no loss in quality.

By taking part in the R2R programme with Aquafil, DAS TEPPICHWERK is actively contributing to reducing waste and conserving natural resources

Products developed by us as part of the Born R2R programme bear the R2R logo to indicate their recyclability along the supply chain.

At the end of their useful life, the carpets can be returned and the ECONYL® nylon components can be regenerated to produce new ECONYL® nylon at Aquafil’s plant in Ljubljana.

One example from the sustainable R2R programme at DAS TEPPICHWERK is the Brilliance quality.